Menu

Metal :Material Removal Surface Operations

Material Removal/Metal Surface Solutions

for castings, stampings, forgings, etc.

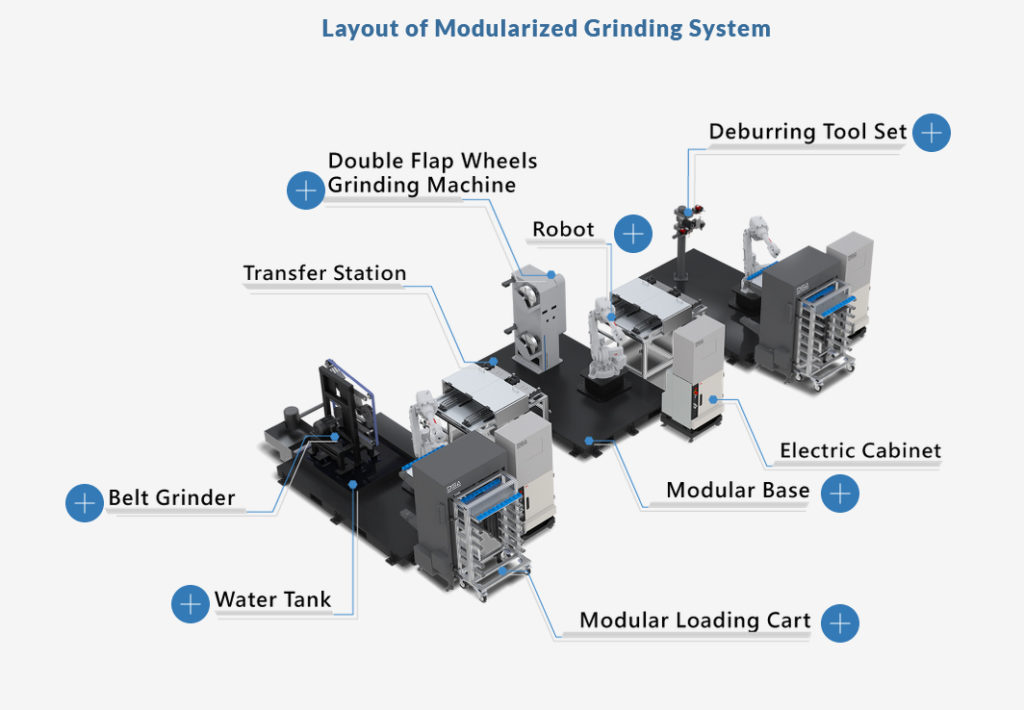

Modularized Grinding System

- Flexible modularization: Various module options, e.g. deburring toolkit, belt grinder, flap wheel, etc.

- Perfect for diverse production: Processes can be planned as needed and can adjust for various orders.

- Complete multiple process station: Can combine deburring, surface sanding, grinding, polishing, etc.

TCP Calibration System

- DT Boost integrates robot and Fork sensors for TCP calibration, with high-precision laser detection and calibration, accuracy is around 0.05 mm. Saving time and optimizing processes.

- High repeatability and option of automated TCP monitoring and recalibration.

- Main applications: Welding, laser cutting, processing, deburring and grinding.

Grinding System Example

Examples of aluminum welded bike frames-first row with raw weld seam, 2nd row with grinding done by standard grinder, 3rd row treated by DTboost robotic grinding system.

Grinding System Introduction

- AR integration enhances efficiency:Tool Center Point (TCP) calibration and the offline programming system saves time and stabilizes quality.

- Robotmaster off-line programming software requires much less human intervention.

- Optional auto sandpaper changer: AI sandpaper changer reduces waste and is very stable.

- Collects information with Smart Machine Box (SMB), monitoring the production and facility status.

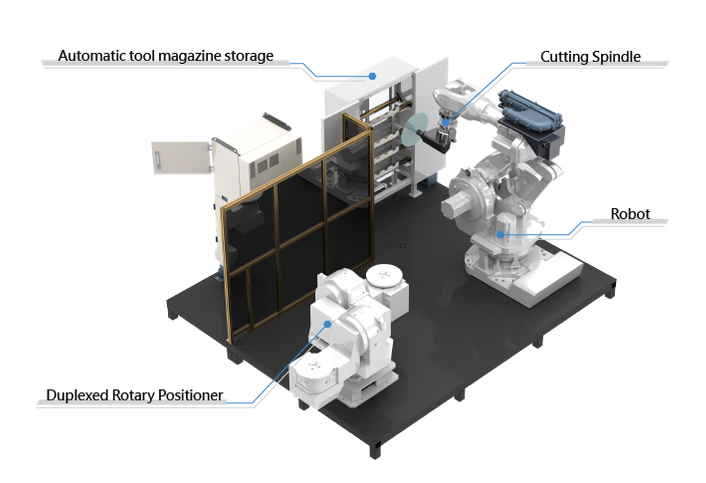

Multi-Function

Robotic Cutting, Deburring, Grinding Machine

- Cutting and grinding.

- Tool magazine robot can change the tool automatically.

- Increases productivity, labor saving & safety.

- Intelligent monitoring system.

- Multi-axis positioning allows the robot to work at multi-angles to process without any blind spots.

- Force Sensor allows the robot to control velocity and power accurately.

- Applied materials: Aluminum & zinc .

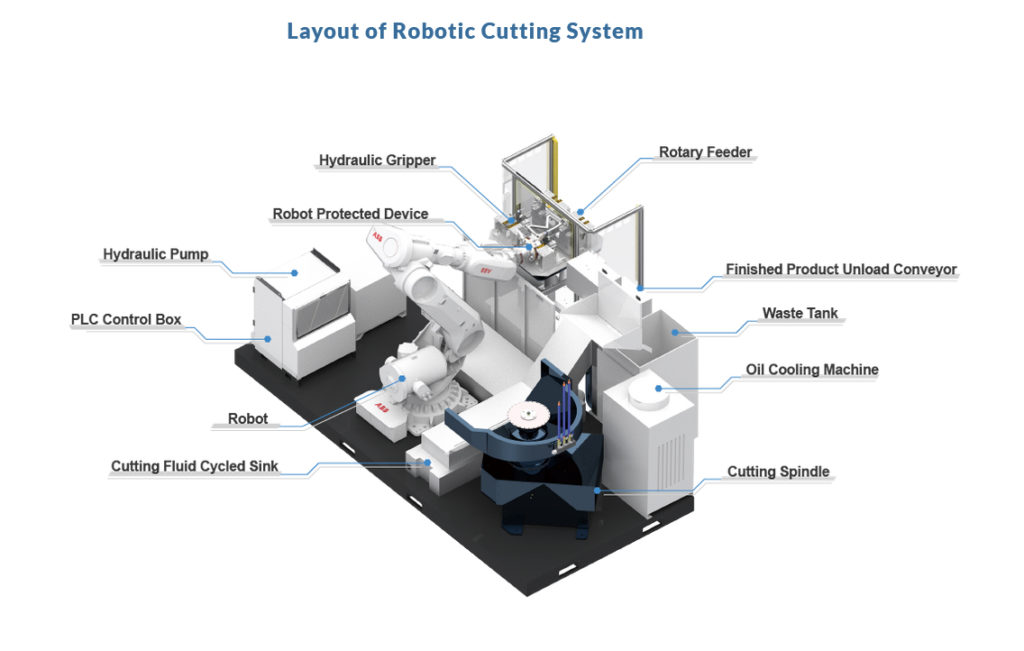

Double Position Rotary Cutter

- Automatic cutting.

- Applied material: Steel, iron, aluminum.

- Double station feeding.

- Intelligent monitoring system.

- Increased productivity, labor saving & safety.

- Cutting Spindle: Floating Type.

- Robot Protected Device: Customized damping gripper.

- Good Surface After Cutting: Maintains metallic luster, no burn marks.

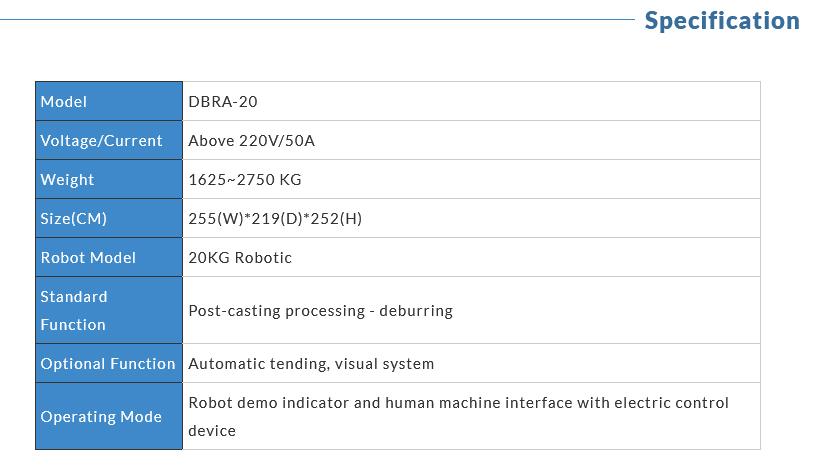

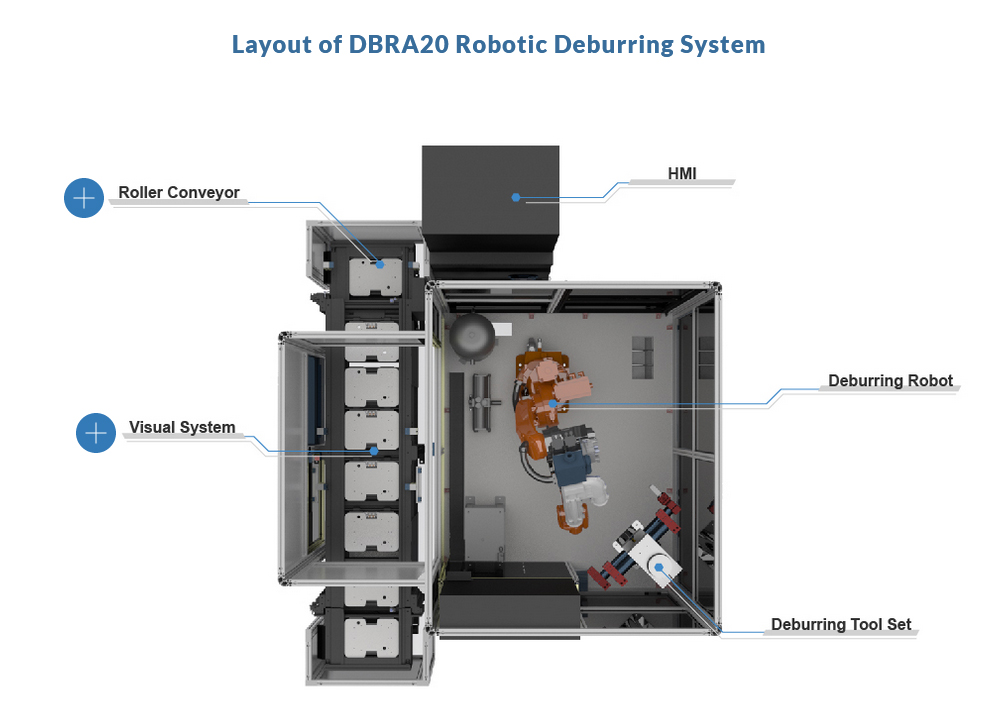

Robotic DBRA20 Deburring System

- Designed for 20KG Robot (robot can be selected according to casting requirements)

- Workstation combines with the fixture to integrate deburring toolkit with conveyor

- Integrates the visual system with the automatic gripper-changing box to make production more flexible

Laser Cleaning/Surface Treatment System

- Coming Soon!

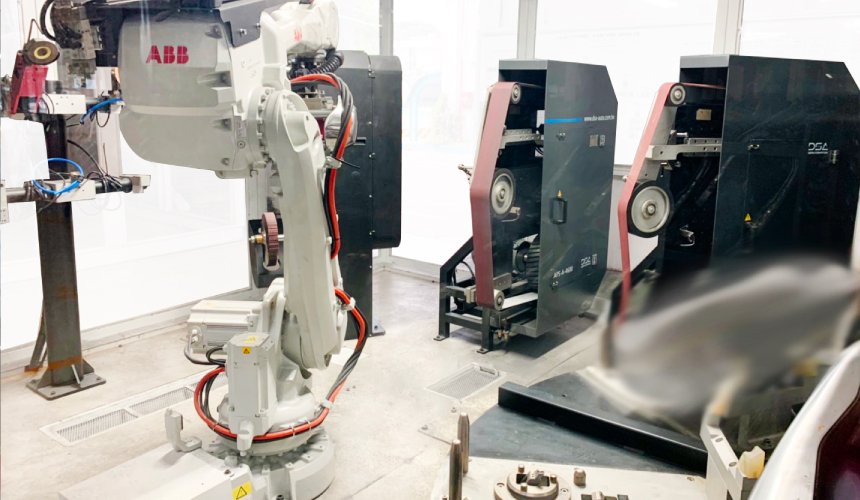

DT Boost is a sister company of DSA-Automation and part of the Meita Group. DT Boost has many years of casting (investment/die/gravity) automation integration design/production experience as well as other metal processing integrations: CNC/Al Welding and various surface treating for unfinished metal parts.

DT Boost Customers