Which Casting Or Surface Processing Equipment?

Which of our Metal Processing Automation Solutions is right for you?

Our experts design and implement the best most cost-effective robot system integration solutions to automate complex applications and make them easy to manage systems-needing the minimum amount or even no human interaction in some cases. Our strongest background is in casting processing of metal in a range of materials including gray cast iron, spheroidal graphite cast iron, vermicular graphite cast iron, high alloy heat resistant cast iron, aluminum alloy, and various cast steel materials. We have provided numerous integrations to customers that have used our equipment to provide parts to Tesla, Daimler, BMW, VW, Audi, Ford, GM, Renault, Stellantis, Toyota, Volvo, etc.

We can build you solutions for individual automated cell systems or larger turn key whole plant “lights out” systems for just about any industrial application.

- Existing module designs (can be modified to better fit your application needs) & customized solutions are all available

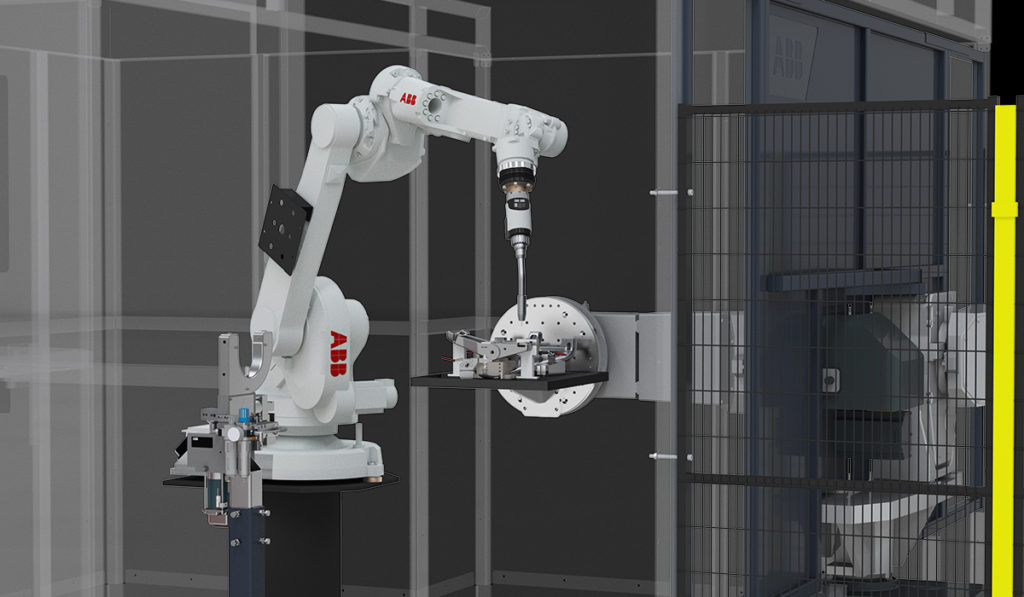

- Our management software and hardware integration can be used just about any robot or cobot brand on the market-we frequently use ABB, Fanuc and Yaskawa. Contact us with your specific needs and we can let you know what the best solution is in terms of lead time and cost.

- Provide both online and in person training on programming and maintaining your system.

- We’ll be happy to answer your questions or sign an NDA to proceed. Please click e-mail button below.

Our experts have over 10 years of experience in Taiwan’s leading investment casting group and have a patented system for providing the best performance in investment casting. Talk to us and we’ll share the key details with you for consideration in your factory!

Investment Casting Automated Solution

Automatic Wax Tree Assembly System

- 3D storage and tray feeding designed to save work space.

- Robot cooperation makes the wax assembly process highly efficienct.

- Tool changing function enhances production flexiblity.

- The soldering iron can be designed according to the wax mold with automatic temperature control.

- The wax joint surface is more solid and smooth because of controllable soldering iron design.

- Customized gripper.

Automatic Wax Cleaning System

- The robot cleans up the parting agent from wax tree after assembly.

- Speeds up the wax drying process.

- Fully automatic production from wax molding process to wax tree assembly saves manpower and improves production efficiency.

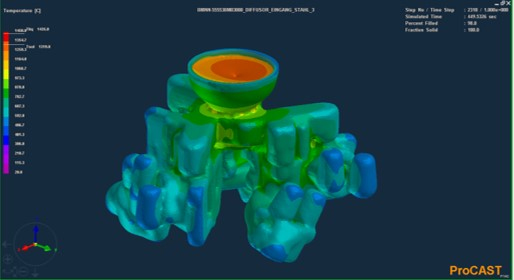

Design and Plan of Wax Tree Assembly Simulation

- Simulates and designs the wax pattern assembly program.

- Simulates the wax pouring result.

- Pre-planned automatic casting cutting.

Welding Automated Solution

Robotic Aluminum Welding System

- Integrated robot and Robotmaster as a physical cyber system for previewing simulations. Not only time saving for programming adjustments and increased efficiency but also enhanced quality & stability.

Features DSA’s own TCP auto adjustment system to enhance time efficiency for robot and off-line program software synchronization. - Integrated multiple axis turntable can machine at different angles without any blind spots.

- The 2 station positioned design speeds up loading and unloading operations.

Automatic Die Casting System

- Replacing humans with machines in a high-risk environment.

- Integrate several die-casting processes with the robot.

- We designed an exceptional gripper that works great in the high temperature environment!

Mold Release Spraying for Die-Casting

- It sprays release agent in specific areas as required.

- Precision spraying of the release agent elevate the casting quality.

- Regulates cooler mold temperature.

- Saves storage space of the spray nozzle module.

Diecasting Automated Solution